Bagged food packaging machines are mainly classified into two types. The first type is form-fill-seal (FFS) machines that utilize roll stock materials—such as polyethylene film or composite plastic film—to shape bags, fill them with measured quantities of powdered, granular, or liquid products, and optionally perform degassing (including re-inflation) before sealing and cutting. The second type includes premade pouch sealing machines, which carry out filling, degassing (with possible re-inflation), and sealing, or only sealing, of already formed pouches.

Heat Sealing Methods for Plastic Films

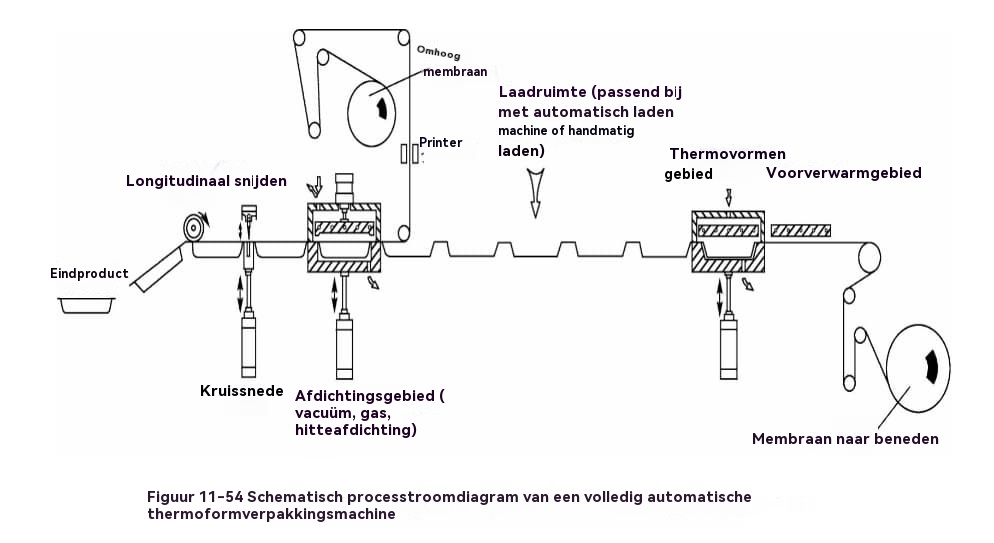

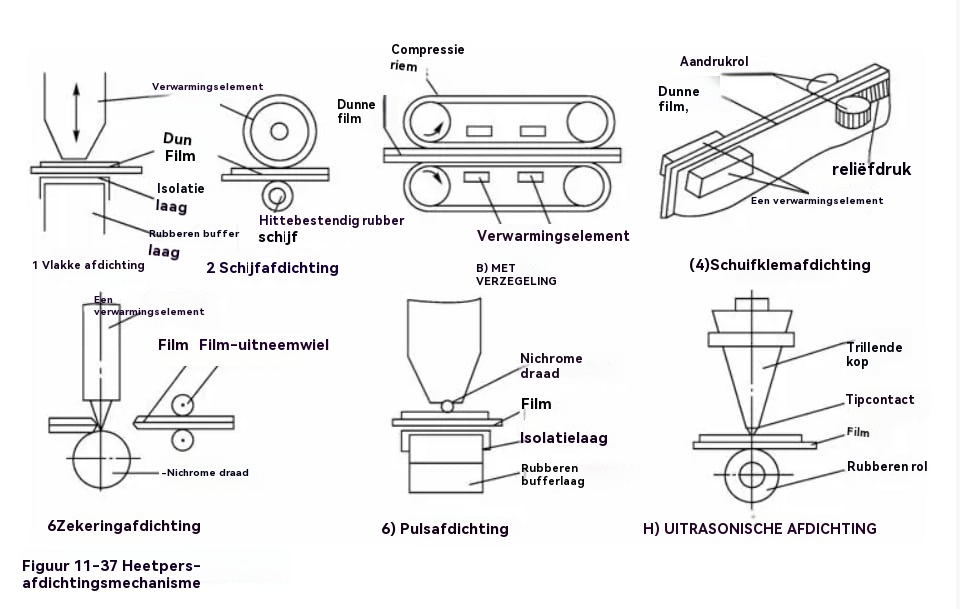

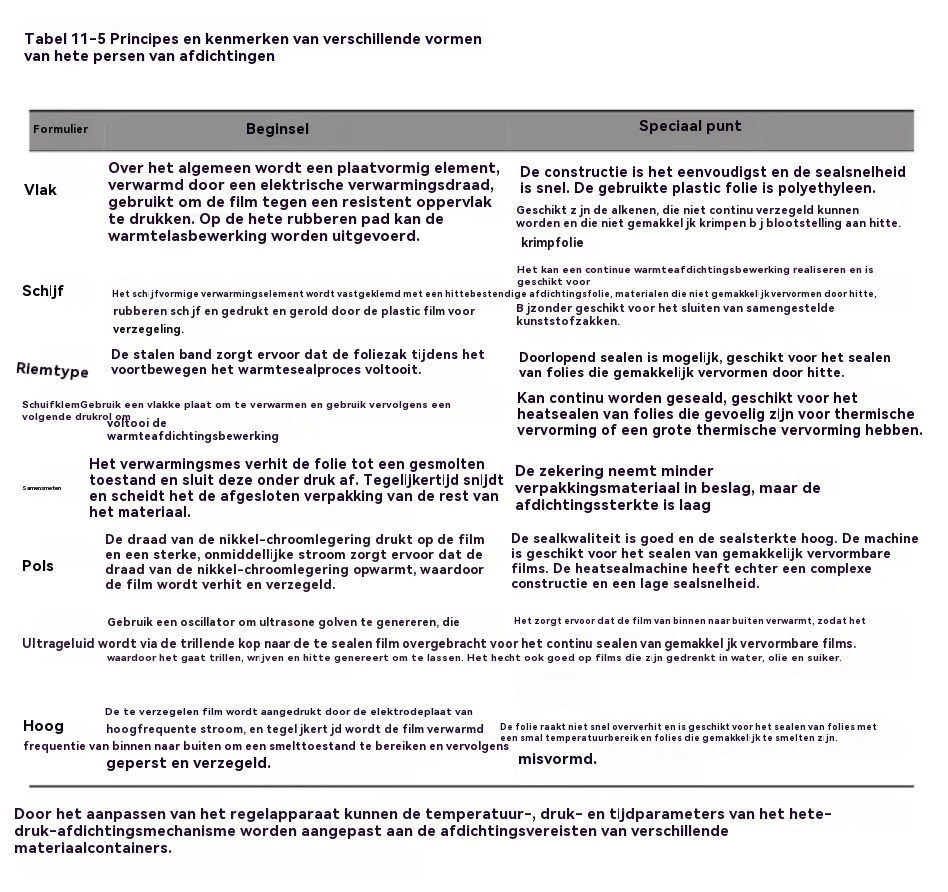

Both form-fill-seal machines and premade pouch sealing machines rely on heat sealing mechanisms to thermally bond packaging materials. As illustrated in figure 11-37, typical heat sealing techniques include flat plate, roller, belt, sliding clamp, and melting cut methods. Table 11-5 summarizes the principles and features of these sealing types. By adjusting control parameters such as temperature, pressure, and timing, the sealing process can be optimized to suit different packaging materials and container types.

Form-Fill-Seal Packaging Machines

Automatic form-fill-seal packaging machines employ reel-fed packaging films to autonomously perform bag formation, filling, sealing, and cutting. This packaging style is suitable for powders, granules, blocks, liquids, and colloidal substances, and is commonly used for small food items, granulated beverages, and instant foods. The films used can be plastic or composite materials. Depending on the machine, bags are formed from either a single film roll or two film rolls, with single-roll machines being more prevalent.

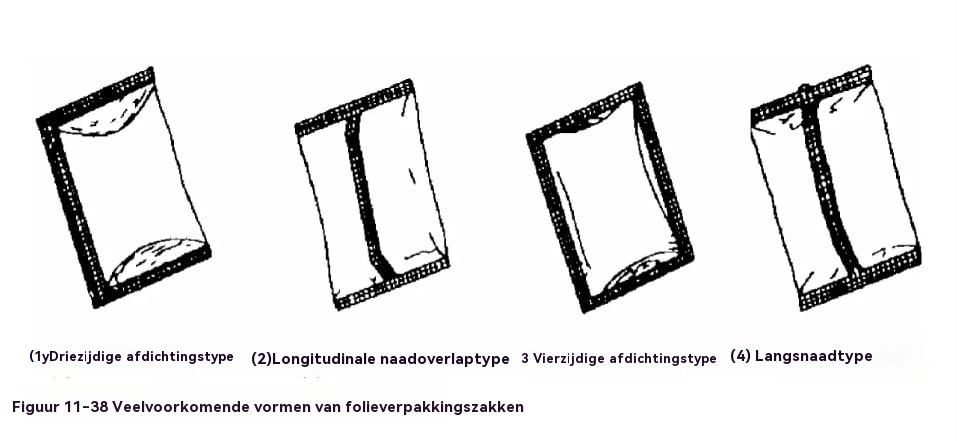

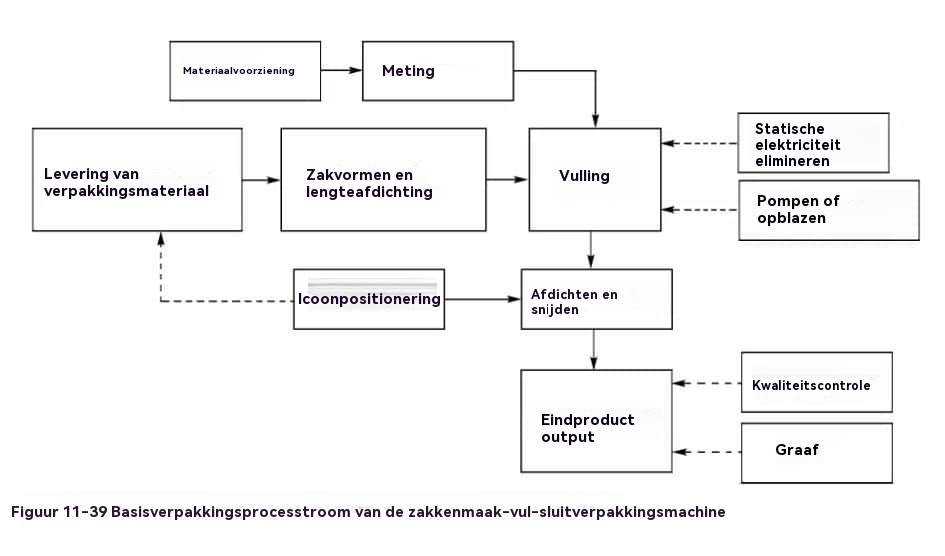

These machines produce various bag types, with the most common being center-seam back seal, four-side seal, and three-side seal (see figure 11-38). Although the specific machine configuration varies with bag type, the core components and operating principles are generally consistent. Figure 11-39 depicts a typical packaging process of a form-fill-seal machine. Variations in structure and process exist depending on the model, but the underlying packaging methodology remains similar.

Form-fill-seal machines are categorized by layout—vertical or horizontal—and by motion type—continuous or intermittent bag making.

Composition and Structure of Form-Fill-Seal Machines

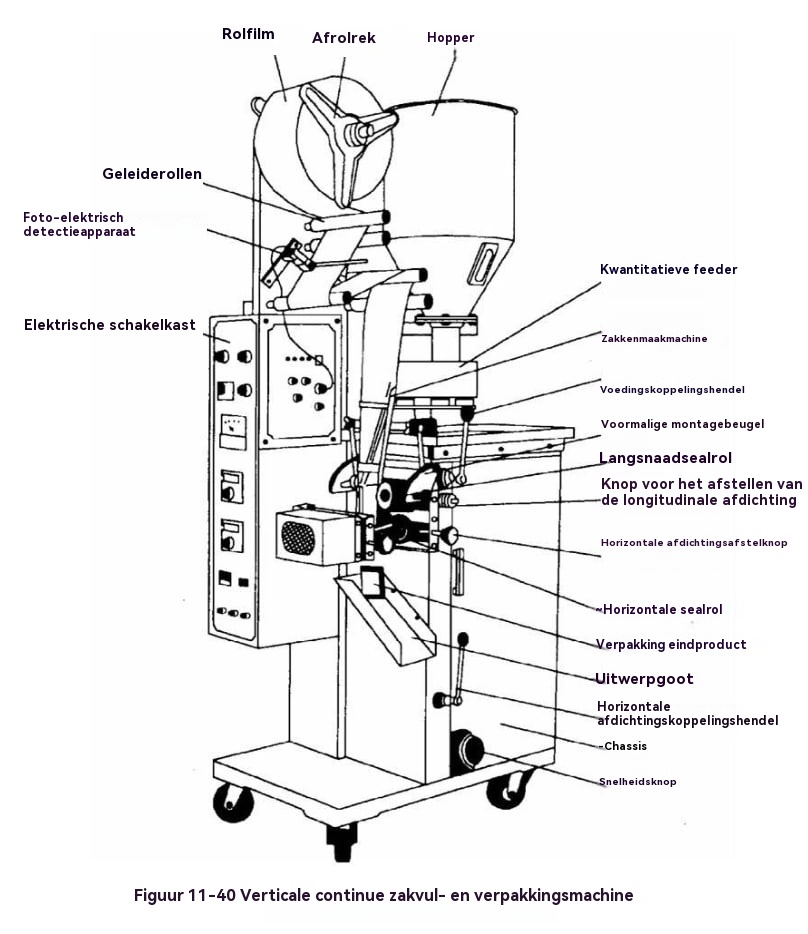

Despite the diversity in models tailored for different materials and bag styles, form-fill-seal machines share fundamental components. For example, a typical vertical continuous form-fill-seal machine (figure 11-40) comprises a drive system, film feeding mechanism, bag forming and sealing units, material dosing device, and an electronic control and detection system. Power and transmission devices inside the machine cabinet drive vertical and cross sealing rollers and volumetric feeders. The film reel on the unwind stand rotates smoothly, and the film is guided through rollers that provide tension, straighten, and align the film accurately.

The bag forming and sealing assembly includes a bag former along with vertical and horizontal sealing devices. Different combinations allow the formation of various bag shapes and seal styles, often serving to differentiate machine types.

Material feeding is performed by volumetric feeders, mostly adjustable volumetric cups for powders and granules. In the illustrated rotary disc feeder, material moves from the hopper into volumetric cups arrayed around the disc’s circumference, then fills the formed film tube automatically.

The electronic control system is central to the machine, allowing parameter setting for vertical and cross sealing temperatures, as well as color mark detection data on printed films, thereby ensuring consistent packaging quality.

Principles of Forming, Filling, and Sealing

Horizontal Forming, Filling, and Sealing

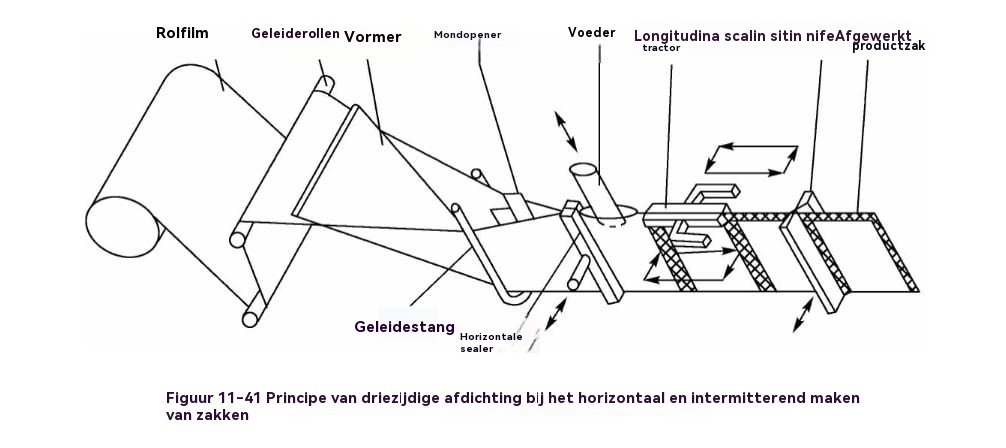

a. Three-Side Seal Bags: As shown in figure 11-41, plastic film from a reel enters the former where it’s shaped into a U-form and opened by a spreader. When the filler descends to the filling position, the cross sealer closes while filling material; then both cross sealer and filler reset. Next, the vertical sealer closes to heat seal and advance the film by one bag length, followed by cutting the sealed bag.

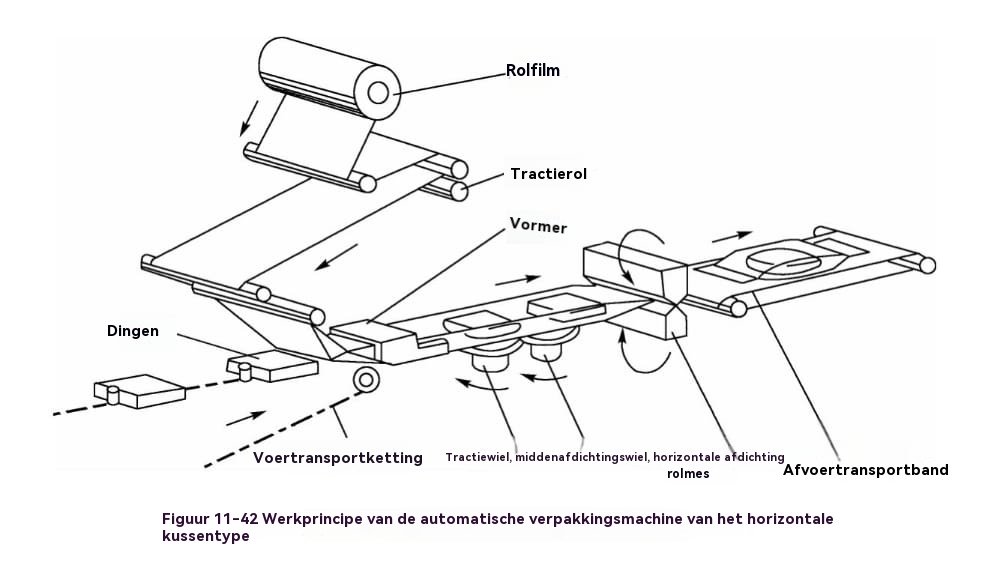

b. Horizontal Pillow Bags: Figure 11-42 illustrates a horizontal pillow-type packaging machine. This continuous operation machine automatically wraps, seals, and cuts products like biscuits and instant noodles. Film from a roll is guided into the former and formed into a roll wrap around the items conveyed by a feeding chain. The film advances under traction, with the center seam sealed by a sealing wheel. Cross sealing and cutting produce the final pillow-shaped package, which is discharged by a conveyor. When colored mark tape is used, an optoelectronic detection system adjusts paper length in real time to ensure precise positioning.

Vertical Forming, Filling, and Sealing

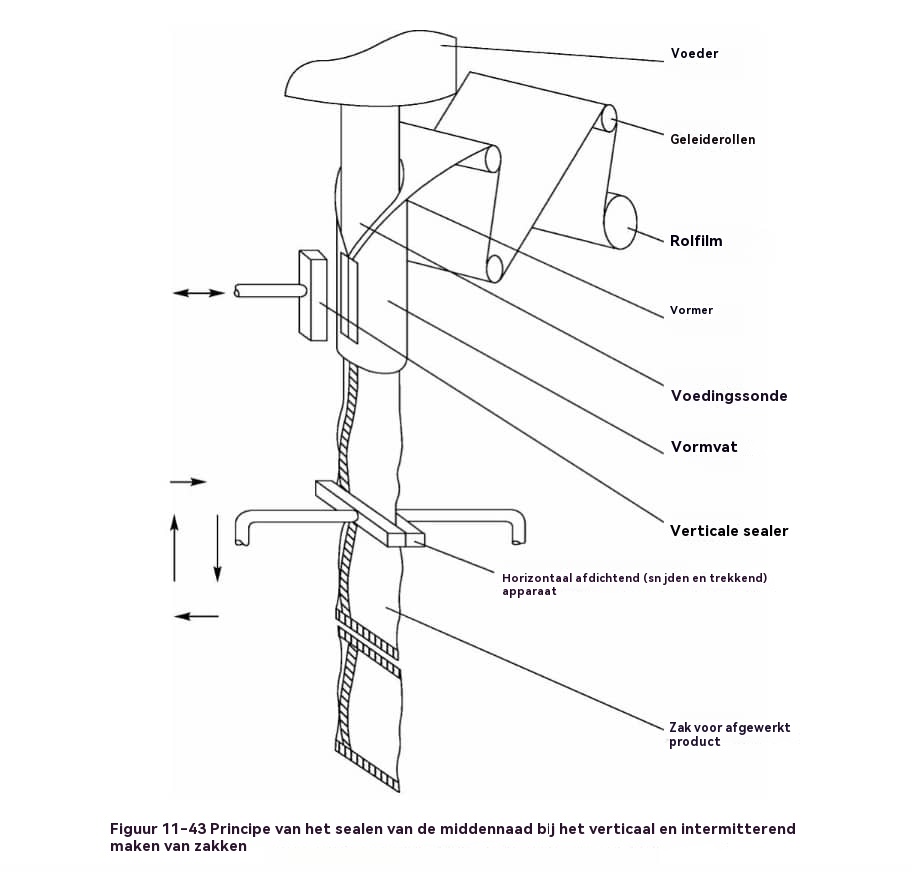

a. Intermittent Bag Forming with Center Seam Sealing: As depicted in figure 11-43, plastic film from a reel is guided into the former to form a cylindrical shape with an overlapping center seam. The filler tube serves as both the bag former externally and material feeder internally. The vertical sealer presses on the overlapped film to heat seal vertically, retracts, then the horizontal sealer seals crosswise while pulling film down by one bag length, sealing and cutting the bags. Each cross seal simultaneously closes the upper bag’s bottom and the lower bag’s top, while filling occurs during film advancement.

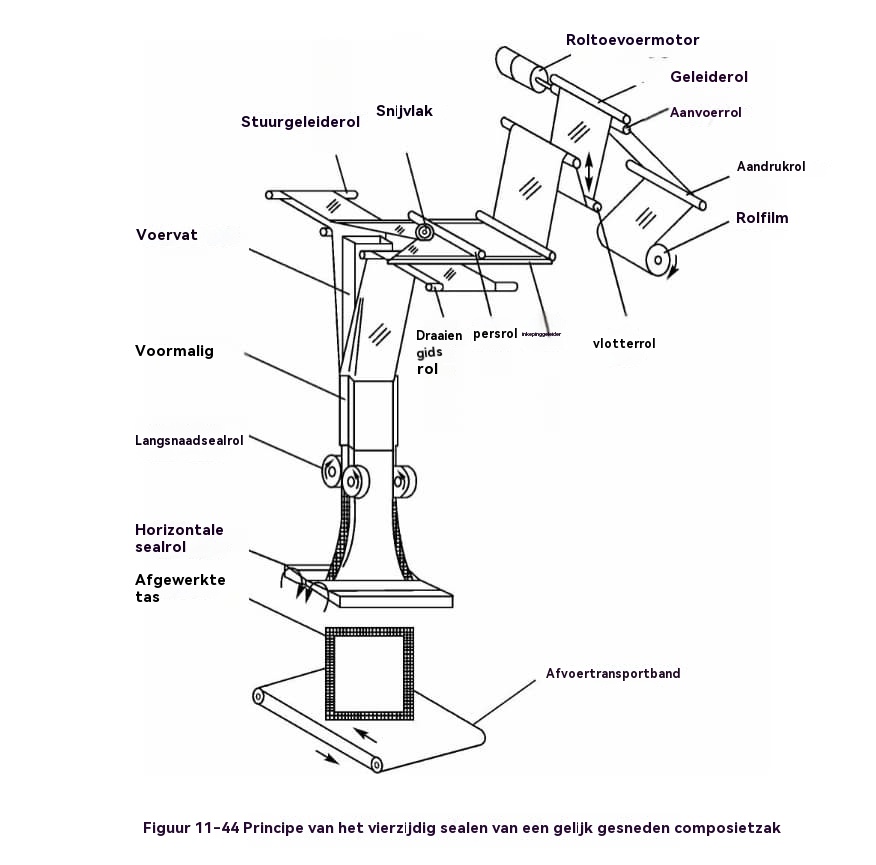

b. Quad Seal Bag Forming: Machines producing quad seal bags may use two reels of film arranged symmetrically and sealed longitudinally before cross sealing and cutting after filling. A single reel quad seal machine (figure 11-44) splits the film in the center and recombines halves during bag forming.

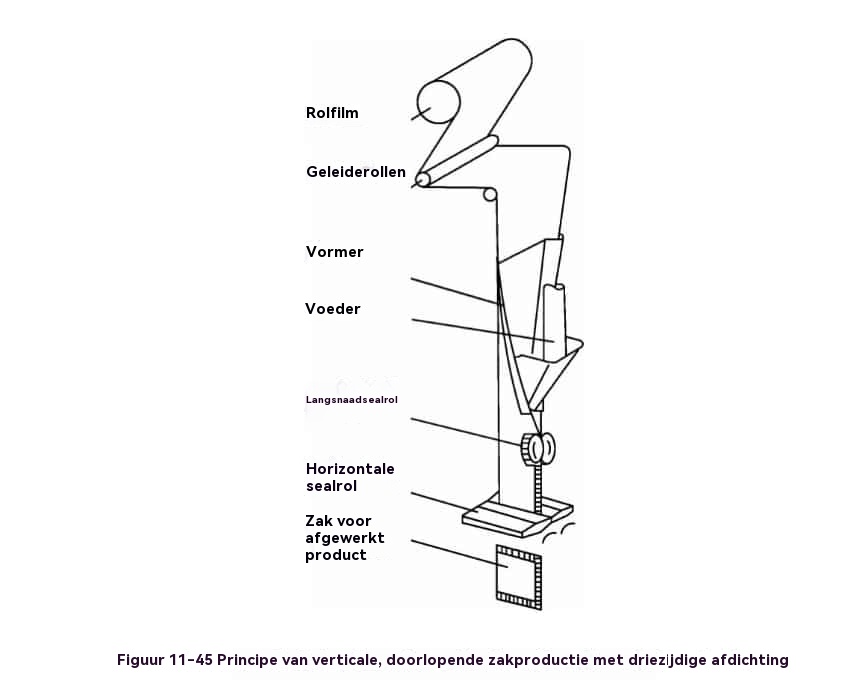

c. Single Reel Three-Side Seal Bag Forming: Using one film reel, this method forms either three-side sealed bags or “fake sealed” quad seal bags (figure 11-45). Pillow packaging (figure 11-46) involves longitudinal sealing after the former, then cross sealing and cutting, producing center seam folded bags with sealed ends.

Premade Pouch Sealing Machines

These machines seal prefilled plastic pouches and include standard sealers, vacuum packaging, and vacuum-inflation packaging machines. Standard sealers with simple heat sealing devices are not discussed in detail.

Vacuum packaging machines often combine vacuum and inflation functions, available in intermittent and continuous types.

Intermittent Vacuum Inflation Packaging Machines

These use composite film pouches, filled and manually placed on the vacuum chamber’s heat seal bar, then automatically vacuumed, inflated, and sealed. Bag size and number per operation vary. Suitable for solids, granules, semi-fluids, and liquids, this method is common in food production for its flexibility and ease of use.

Types of Intermittent Vacuum Inflation Machines

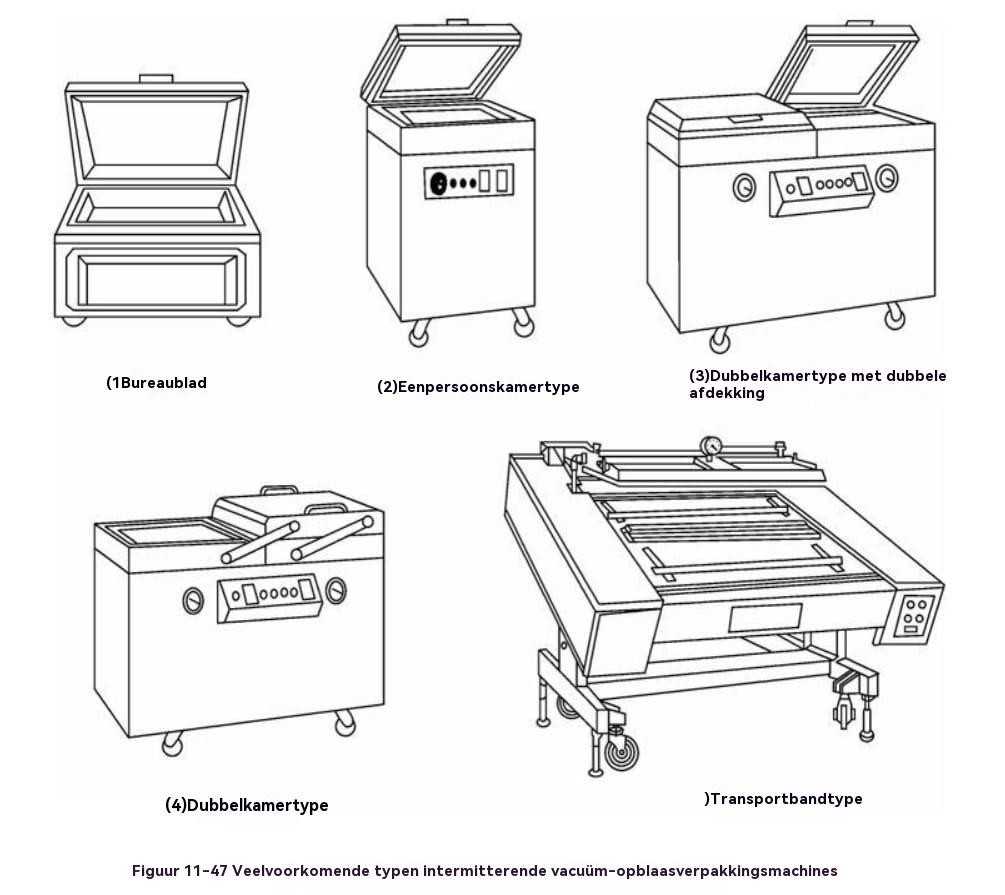

Figure 11-47 shows common types: tabletop, single-chamber, double-chamber (single- or double-lid), and inclined (conveyor belt) models. Vacuum levels reach 1–2 kPa absolute pressure, with production speeds of 2–4 cycles per minute.

Tabletop and single-chamber machines have a single short heat seal bar, suited for lab or small batch use. Double-chamber machines share vacuum and inflation systems between two chambers, improving efficiency by allowing one chamber to seal while the other is loaded/unloaded.

The vacuum chamber’s horizontal bottom surface complicates sealing products with much liquid, as the sealing mouth must be propped above the chamber bottom to prevent leakage, limiting suitability for high-liquid products.

Conveyor belt (inclined) vacuum inflation machines feed products automatically into the chamber, raising automation and throughput. The inclined chamber bottom prevents liquid spillage during sealing.

Working Principle of Intermittent Vacuum Inflation Machines

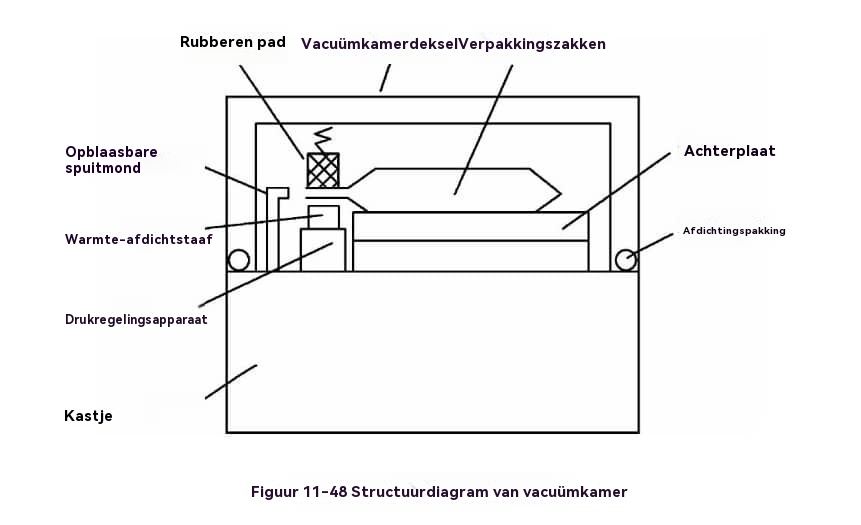

Excluding conveyor belt models, these machines consist of a main body, vacuum chamber, heat sealing device, lid lifting mechanism, vacuum system, and electronic controls.

The vacuum chamber (figure 11-48) is where sealing occurs. Figure 11-49 illustrates the vacuum inflation sealing cycle comprising:

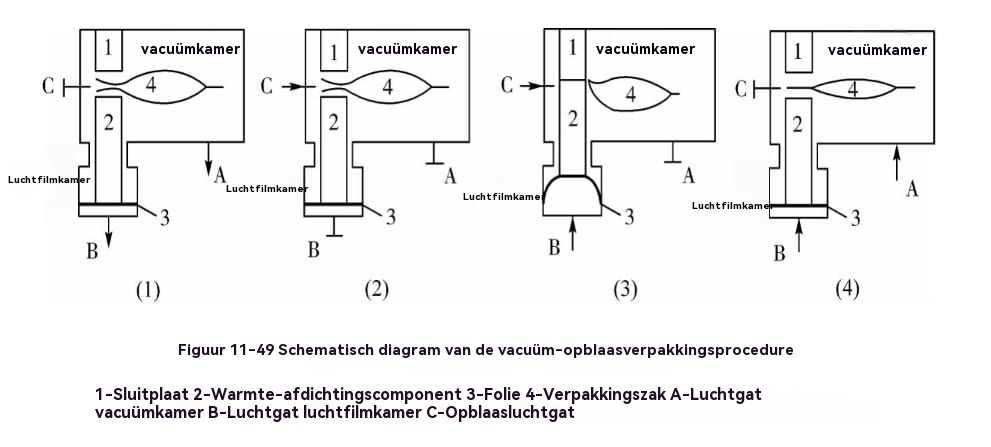

a. Vacuum Pumping: Evacuates the vacuum chamber and lower air film chamber to equalize pressure, preventing the film from bulging and losing vacuum. Vacuum level targets -0.097 to -0.0987 MPa.

b. Inflation: After sealing air holes A and B, inert gas is introduced at 3–6 kPa to inflate the package, controlled by a timer. Vacuum in the chamber is maintained between -0.097 and -0.094 MPa. Inflation is skipped for cooked products undergoing later sterilization.

c. Heat Sealing and Cooling: With venting hole B open, atmospheric pressure presses the film against the sealing pad, while the sealing bar heats to seal. After sealing, power is cut to allow cooling while pressure is maintained, ensuring a strong seal.

d. Venting: Air fills the vacuum chamber, balancing pressure to open the lid and remove the sealed package.

Rotary Vacuum Packaging Machines

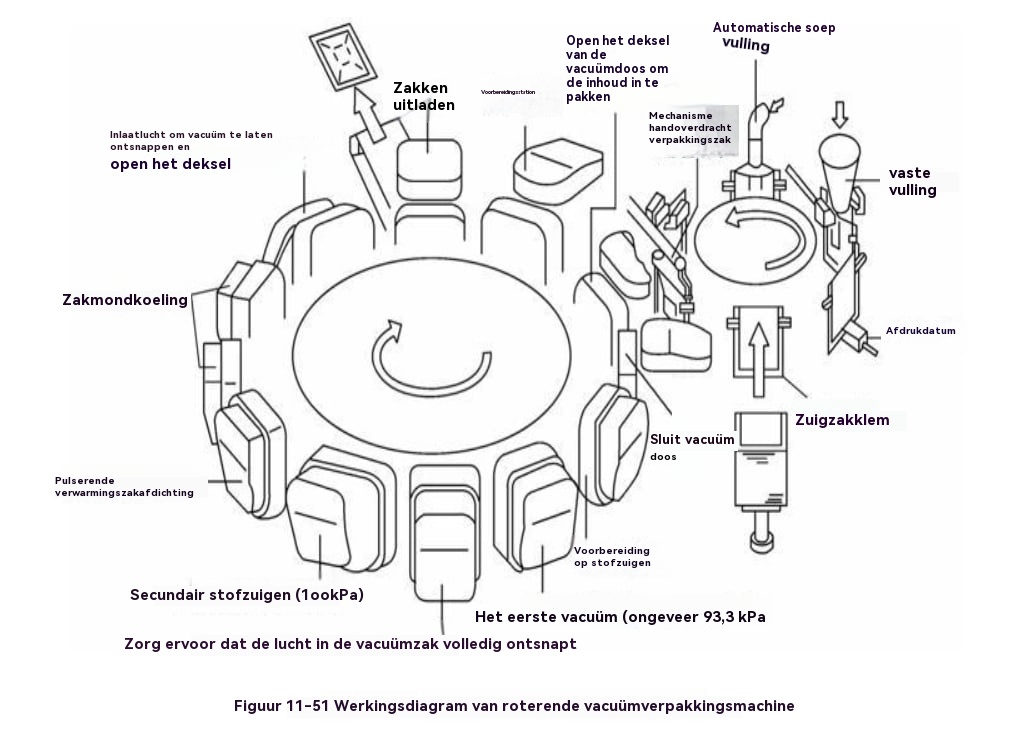

Figures 11-50 and 11-51 depict a rotary vacuum packaging machine with a filling and vacuum turntable. A mechanical arm transfers filled bags between stations.

The filling turntable includes 6 stations for bag supply, printing, opening, solid filling, and liquid injection. The vacuum turntable has 12 vacuum chambers where vacuum pumping, heat sealing, cooling, and unloading occur in cycles, achieving up to 40 bags per minute. Solid dosing must match the filling station.

Thermoforming Packaging Machinery

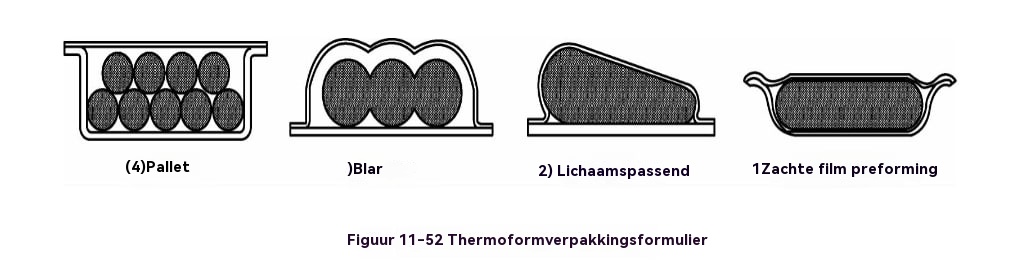

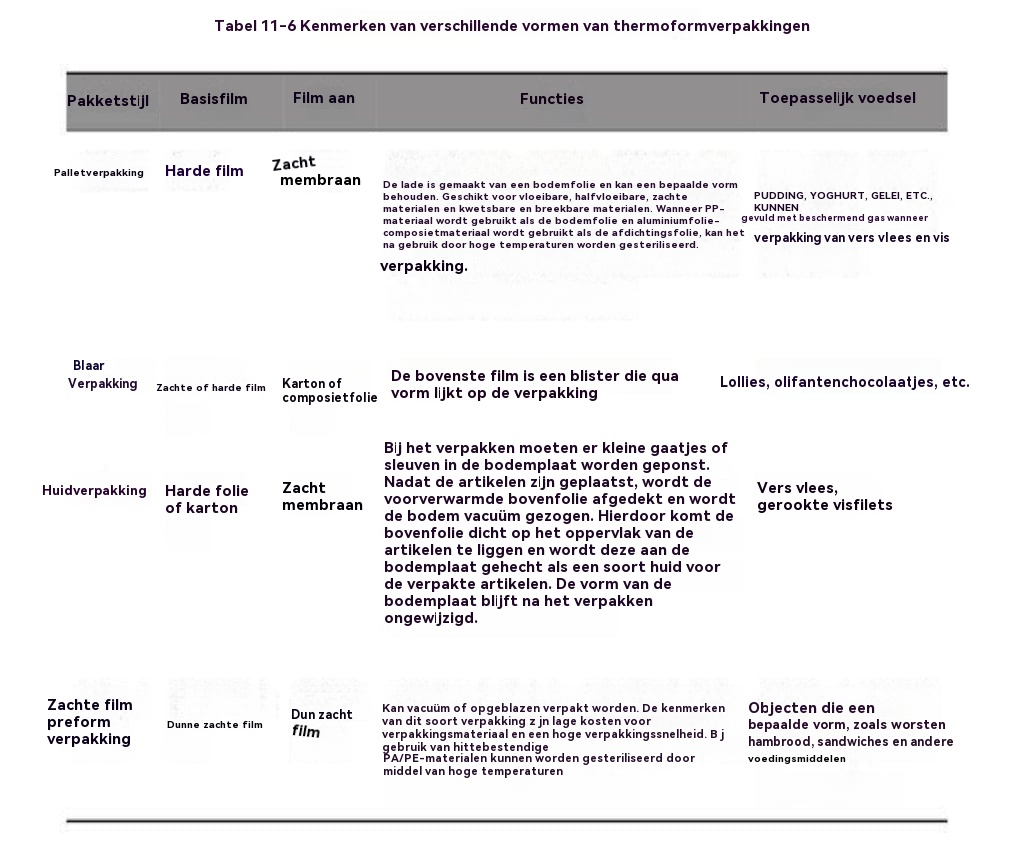

Thermoforming packaging uses thermoplastic sheets to form containers, which are then filled and sealed with films or sheets. Common forms include tray, blister, skin, and soft film preformed packaging (figure 11-52). Table 11-6 compares their features.

Thermoforming equipment ranges from manual to fully automatic. The process involves clamping, heating, pressurizing/vacuuming, cooling, and demolding. These machines produce packaging containers only; filling and sealing require separate equipment.

Fully automatic thermoforming machines combine forming, filling, and sealing, using reel-fed thermoplastic films for bottom forming and top sealing. This integration eliminates the need for pre-manufactured boxes, streamlining production for food manufacturers. These versatile machines support various packaging forms shown in figure 11-52.

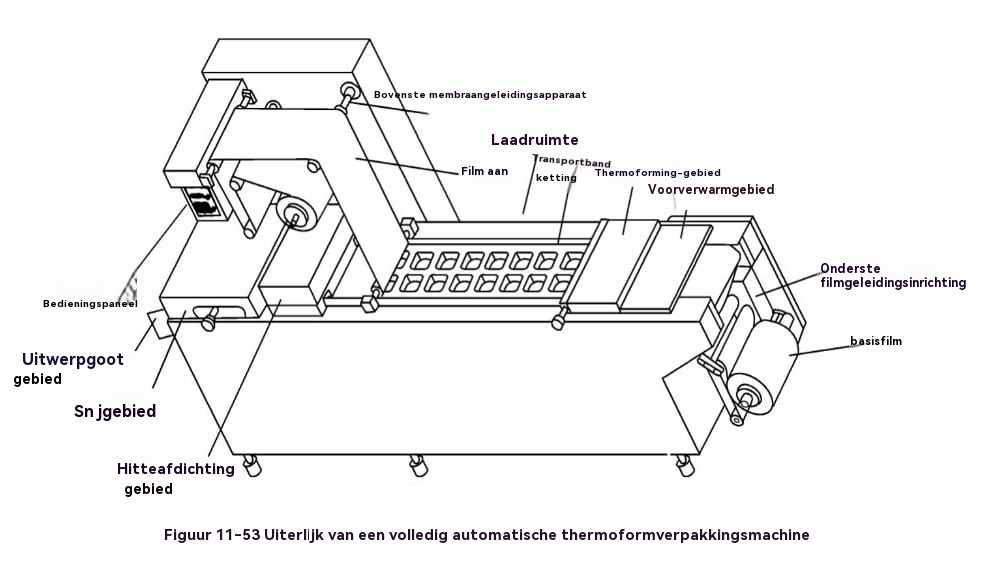

Figure 11-53 shows a fully automatic thermoforming machine with components including film conveying, film guiding, bottom film preheating, forming, filling, heat sealing, cutting, and control systems.

Figure 11-54 outlines the packaging flow: bottom film is drawn through preheating and forming zones (air pressure, vacuum, or punching), filled in the filling area, then covered by the top film. Vacuum or protective gas treatment may be applied before heat sealing. Finally, packages are shaped by cross cutting, longitudinal cutting, and corner trimming. Waste edges are collected by suction or winding devices.